Introduction:

In today’s agricultural landscape, precision farming has emerged as a critical approach to enhance resource usage, increase yields, and promote sustainability. Precision farming is possible with the use of advanced technologies such as encoders. In this article, we’ll delve into the concept of encoders and explore their significance in revolutionizing agriculture.

Table of Contents

Understanding Encoders:

Encoders are sophisticated devices designed to measure the position, speed, or rotation of shafts or objects with remarkable accuracy.

The Role of Encoders in Precision Farming

What is Precision Farming?

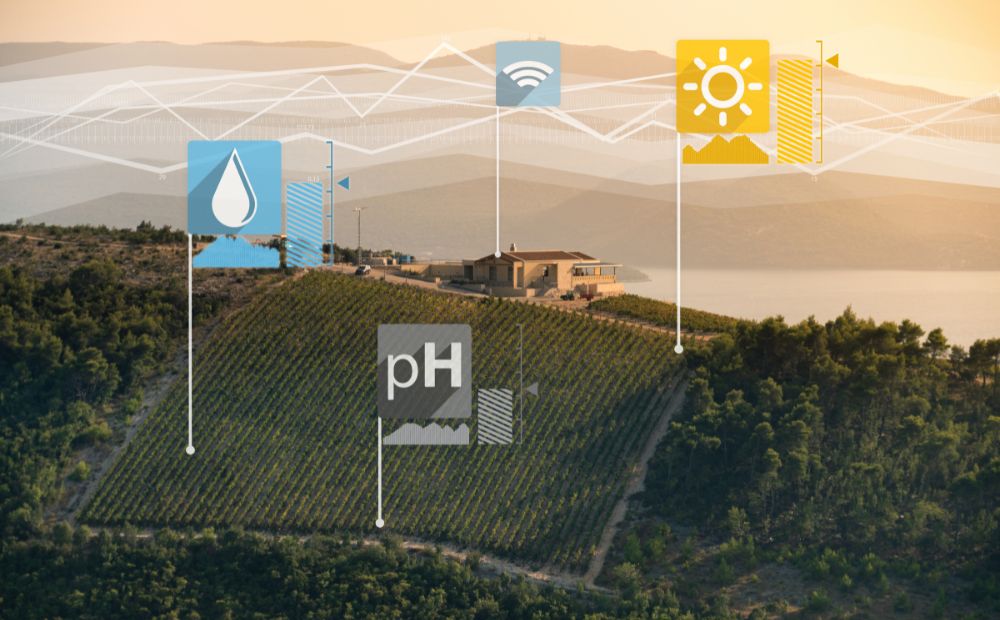

Precision farming, also known as precision agriculture, is an approach that utilizes technology to optimize crop production efficiency and sustainability. It involves the precise management of resources such as water, fertilizers, and pesticides, tailored to specific conditions within a field. By integrating data from sensors, GPS, and other technologies, precision farming enables farmers to make informed decisions, reduce waste, and maximize yields.

There are Two Main Types of Encoder:

Absolute and Incremental

While absolute encoders provide precise position information without requiring a reference point, incremental encoders generate pulses as the shaft rotates, allowing for continuous monitoring of movement or rotation.

In Precision agriculture, both absolute and incremental encoders play crucial roles in ensuring accurate positioning, control, and data collection in various agricultural processes.

Encoders Can Also be Classified As:

Optical encoders:

Use an optical sensor to detect and measure physical quantities such as linear axis movement and rotation angle .Optical encoders are widely used in both absolute and incremental encoder designs. Their versatility makes them indispensable in various applications requiring accurate position and velocity measurements, such as robotics, CNC machines, and motion control systems.

Rotary encoders:

Sensors that detect position and speed by converting rotational mechanical displacements into electrical signals

Magnetic encoders:

Used in many different types of applications, including measuring speed and monitoring motor activity .

Comparison

Absolute Encoder:

Precise Positioning: Absolute encoders provide accurate position information without the need for a reference point. This precision is essential for tasks like autonomous navigation of agricultural vehicles, where knowing the exact position is critical for efficient operation.

Power Loss Tolerance: Absolute encoders retain position information even if power is lost, which is particularly valuable in applications where continuous operation is necessary, such as autonomous vehicles or irrigation systems. This capability ensures that equipment can resume operation without the need for recalibration.

Optimized Resource Management: By accurately determining the position of machinery and equipment, absolute encoders help optimize resource management in precision agriculture. This includes precise application of fertilizers, pesticides, and water, leading to improved crop yield and reduced environmental impact.

Incremental Encoder:

Relative Position Measurement: Incremental encoders generate pulses as the shaft rotates, allowing for relative position measurement. While they require a reference point for determining absolute position, incremental encoders are well-suited for tasks where continuous monitoring of movement or rotation is necessary.

Cost-effectiveness: Incremental encoders are generally simpler and more cost-effective than absolute encoders. This makes them suitable for applications where high precision is not required, but continuous monitoring of movement or rotation is still necessary, such as monitoring equipment like weather stations or soil moisture sensors.

Automation and Data Collection:

Incremental encoders contribute to automation and data collection in precision agriculture by providing real-time feedback on the movement of machinery and equipment. This data enables farmers to monitor and optimize various processes, such as planting, harvesting, and irrigation, leading to increased efficiency and productivity.

Overall, both absolute and incremental encoders are essential components of precision agriculture systems, enabling accurate positioning, control, and data collection for improved resource management and crop production.

Significance of Encoders in Agriculture

Precision Farming:

Encoders play a pivotal role in achieving precision in farming operations. By enabling precise positioning and control of agricultural machinery, such as tractors, planters, and harvesters, encoders ensure tasks like planting, fertilizing, and harvesting are executed with utmost accuracy. This precision not only improves crop quality but also reduces waste and boosts profitability for farmers.

Automation and Robotics:

The integration of encoders in autonomous agricultural vehicles and robotic systems is transforming farming practices. Encoders facilitate precise navigation, obstacle avoidance, and operation of robotic arms, enabling tasks like picking fruits or spraying pesticides to be carried out autonomously. This automation reduces labor costs, enhances operational efficiency, and enables round-the-clock farming operations.

Resource Management:

Encoders contribute significantly to efficient resource management in agriculture. By providing accurate position and control feedback, encoders optimize the application of water, fertilizers, and pesticides, minimizing waste and environmental impact. This precision resource utilization is crucial for promoting sustainability and ensuring the long-term viability of farming practices.

Enhancing Encoder Applications in Agriculture through AI and IoT Integration

In agriculture AI and IoT can enhance encoder applications in several ways:

Precision Farming:

AI algorithms can analyze data from IoT sensors deployed in the field, such as soil moisture levels, weather conditions, and crop health indicators. This data can be used to optimize encoder settings for agricultural machinery, such as crop sprayers and harvesters, ensuring precise operation tailored to specific field conditions.

Crop Monitoring and Management:

IoT sensors, such as drones equipped with cameras or ground-based sensors, can collect data on crop growth, pest infestations, and soil quality. AI-powered image analysis can process this data to detect issues early and optimize encoder settings for tasks like monitoring irrigation systems or controlling robotic harvesters.

Supply Chain Optimization:

AI algorithms can analyze data from IoT sensors embedded in transportation vehicles and storage facilities to optimize encoder settings for tasks like tracking inventory, managing logistics, and ensuring product quality during transit.

Predictive Analytics:

AI can analyze historical data from IoT sensors to predict crop yields, market demand, and pricing trends. This information can inform encoder settings for tasks like crop planning, resource allocation, and marketing strategies.

Smart Irrigation:

IoT sensors can monitor soil moisture levels, weather forecasts, and crop water requirements in real-time. AI algorithms can analyze this data to optimize encoder settings for irrigation systems, ensuring efficient water usage and maximizing crop yield while minimizing environmental impact.

Livestock Management:

IoT sensors can monitor animal health, behavior, and environmental conditions in livestock facilities. AI-powered analytics can process this data to optimize encoder settings for tasks like automated feeding systems, temperature control, and disease detection.

Market Growth Driven by Rising Demand for Encoders Across Diverse Sectors

By integrating AI and IoT technologies into encoder applications in agriculture, farmers can make data-driven decisions, optimize resource utilization, and improve overall efficiency and sustainability in agricultural operations.

Encoder Market Analysis:

The encoder market is poised for substantial growth, with an estimated value of USD 3.08 billion in 2024, projected to soar to USD 4.5 billion by 2029, marking a robust CAGR of 7.91% during the forecast period (2024-2029).

Key Growth Drivers:

The market is witnessing upward growth due to the increasing demand for encoders across various sectors, ranging from data centers to telecommunication.

Driving Forces:

The escalating need for high-end automation, coupled with the advent of Industry 4.0, stands as the primary catalysts propelling market expansion. Industry 4.0 heralds a new era wherein factory automation transcends conventional boundaries, shifting towards a cloud-based infrastructure that facilitates big data analytics and the virtualization of production processes.

Global Initiatives:

Countries worldwide are actively embracing Industry 4.0, spearheading strategic initiatives to fortify its implementation. Notably, initiatives like SAMARTH Udyog Bharat 4.0, orchestrated by the Ministry of Heavy Industry & Public Enterprises, Government of India, underscore the commitment to enhancing competitiveness in the Indian Capital Goods Sector.

Leadership in Investment:

According to UNCTAD, China and the United States emerge as frontrunners in investment and capacity within Industry 4.0 technologies. These nations boast the largest digital platforms, commanding a staggering 90 percent of the market capitalization.

Central Role of Encoders:

Encoders occupy a central position in motion control applications, furnishing crucial feedback on position, speed, and direction to controllers or drives. This facilitates increased accuracy and reliability within drive systems. As technological advancements march forward, encoders evolve in tandem, integrating cutting-edge communication and networking capabilities, empowering engineers with versatile solutions to tackle an array of challenges across diverse motion control applications.

Challenges and Future Directions:

While encoders offer immense potential for enhancing precision farming, challenges such as cost, maintenance, and compatibility with existing equipment need to be addressed. Emerging technologies like IoT integration and AI-driven analytics hold promise for further advancing the role of encoders in agriculture. Collaboration and innovation are key to overcoming these challenges and unlocking the full potential of encoder-based precision farming solutions.

Here are the top Encoder Companies:

Omron Corporation

OMRON is a Japanese electrical equipment manufacturer that develops and provides Industrial Automation Solutions.

Honeywell International

Honeywell manufactures encoders as part of its broader portfolio of industrial automation solutions.

Schneider Electric:

Schneider Electric produces encoders for use in motion control systems, robotics, and industrial automation.

Rockwell Automation Inc.

Rockwell Automation is a leading provider of industrial automation solutions, including encoders.

Panasonic Corporation

Panasonic manufactures encoders for use in a wide range of applications, including robotics, CNC machines, and automotive systems.

Baumer Group:

Baumer is a specialized manufacturer of sensors and encoders for industrial applications. Their encoders are designed to withstand harsh environments and provide accurate feedback for precise motion control.

Renishaw PLC:

Renishaw specializes in high-precision measurement and motion control solutions, including encoders.

Dynapar Corporation:

Dynapar is a leading manufacturer of encoders and resolvers for motion control and automation applications.

Faulhaber Drive System:

Faulhaber manufactures miniature encoders for use in compact and high-precision applications such as medical devices, robotics, and aerospace systems.

Maxon Motor AG:

Maxon Motor specializes in high-precision drive systems, including encoders. Their encoders are used in various industries, including robotics, medical devices, and aerospace, where precise motion control is essential for performance and safety.

Conclusion:

Encoders play a crucial role in modern agricultural practices by providing accurate feedback for precision farming, enabling automation in agricultural machinery, and contributing to data-driven decision-making in agriculture. As technology continues to advance, encoders will likely evolve to meet the evolving needs of the agricultural industry, empowering farmers with versatile solutions to enhance productivity and sustainability. By harnessing the power of encoders, we can pave the way towards a more sustainable and prosperous future for agriculture.

Signup For AgriNext Conference Newsletter